Cyber Physical Assembly Line

At FSM's Cyber Physical Factory, the Cyber Physical Assembly Line is an advanced setup designed to demonstrate smart manufacturing solutions using cutting-edge Industry 4.0 technologies. This assembly line integrates three fully automated workstations, each utilizing different automation platforms and communication protocols, showcasing the seamless collaboration between diverse systems in a manufacturing environment.

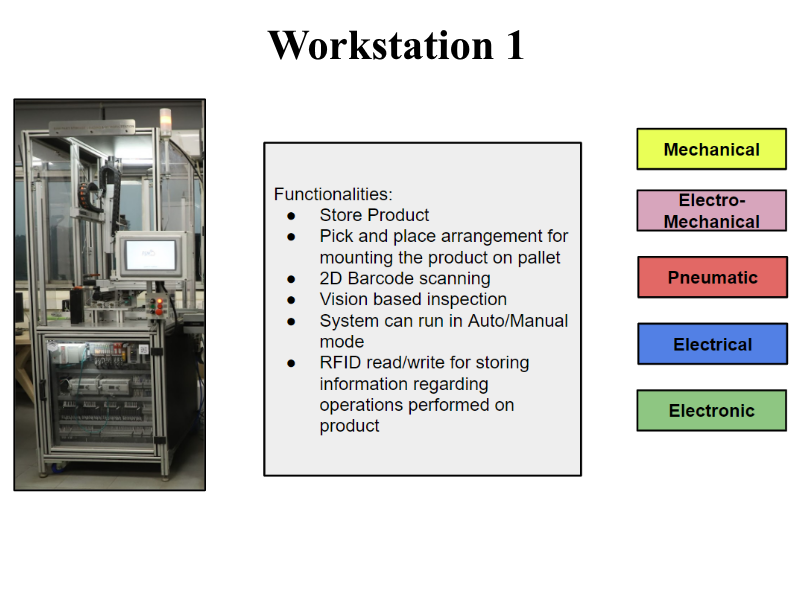

Workstation 1: Inventory Management and Quality Control

This station handles inventory management and performs quality checks using QR code scanning and vision sensors. The system automatically selects the correct workpiece from the inventory, inspects all sides, and transfers it to the next station on a pallet equipped with RFID technology.

-

- PLC Used: Allen-Bradley/Rockwell (Ethernet IP)

- Communication: OPC UA

- Programming: Ladder Logic, Pneumatics, and 4-Axes Motion Control

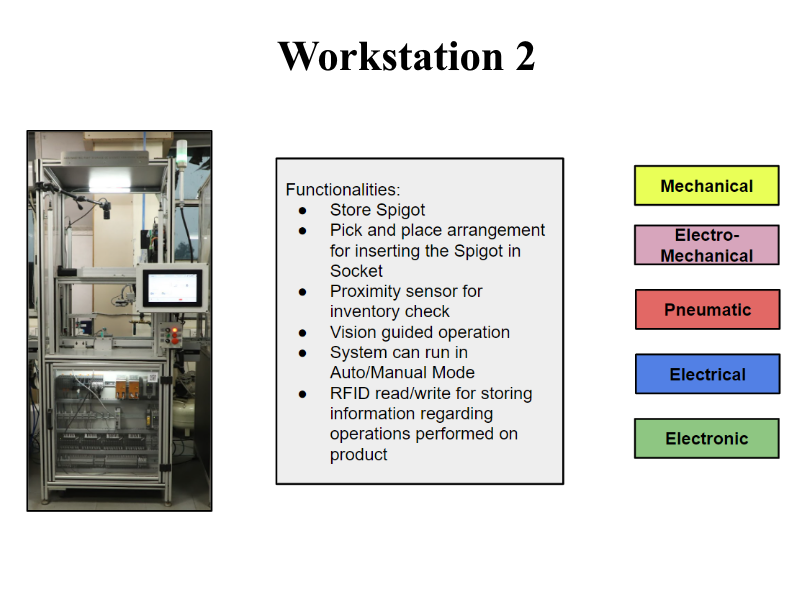

Workstation 2: Child Part Insertion

Workstation 2 is responsible for inserting the child part into the base part. With automated part picking using grippers and precise motion control, this station ensures accurate assembly of the child part.

-

- PLC Used: B&R (Powerlink)

- Communication: OPC UA

- Programming: Structured Text, Pneumatics, and 3-Axes Motion Control

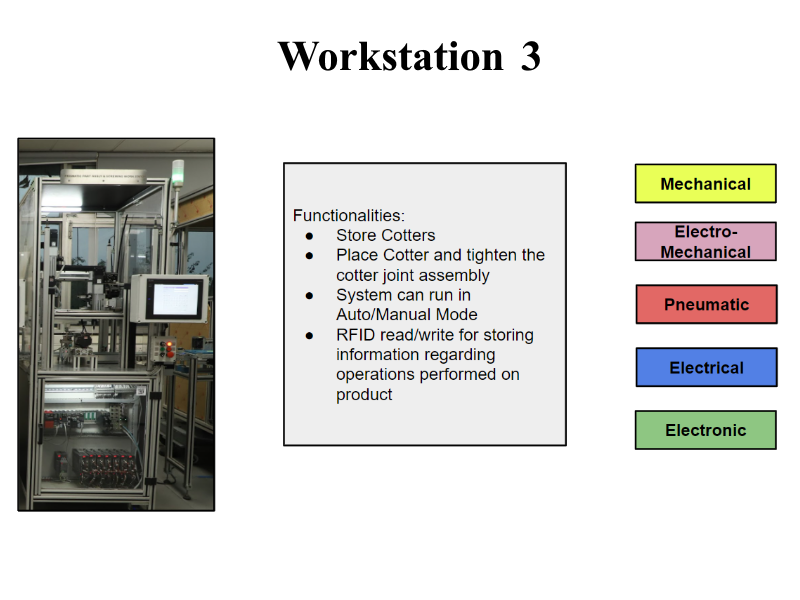

Workstation 3: Final Assembly

At the final station, the assembly is completed by attaching additional components to the assembled parts using a pneumatic gripper and torque-controlled screwdriver. The station also utilizes vision systems for alignment and ensures that each component is correctly fastened.

-

- PLC Used: Mitsubishi (Profinet, CC-Link)

- Communication: OPC UA

- Programming: Ladder Logic, Pneumatics, and 7-Axes Motion Control

Smart Communication and IIoT Integration

The entire assembly line operates using OPC UA for communication between machines and the server, enabling real-time data exchange and remote monitoring. Through an Industrial Internet of Things (IIoT) system, the assembly line is connected to edge devices and a cloud-based dashboard, allowing for seamless data flow, predictive maintenance, and production control.

The assembly line also demonstrates flexible control through a mobile app, enabling users to place customized production orders that are sent directly to the machines, initiating automated workflows without human intervention.